The first automatic wire head machine was localized in Iran to meet the needs of one of the industrial centers, with the continuous follow-up of the comprehensive industrial system, Shamsta, by one of the experts who is a member of the Shamsta industrial system. The machine was localized and delivered to the requesting company in the month of Ordibehesht.

The sixth day of Ordibehesht is an important day in the history of the comprehensive industrial system, Shamsta. It is a day when one of its main objectives, utilizing the expertise in meeting the country's needs, is achieved. At this time, one of the important and key needs of the country's industry was manufactured and delivered to the requesting factory using the capacities and scientific and technical capabilities of one of the experts and industrial centers affiliated with this system. The need for an automatic wire head machine was referred to the Shamsta comprehensive industrial system in 2022 by one of the country's major factories in the field of manufacturing industrial panels. After announcing this need, Shamsta's technical experts visited the factory to better understand the requirements and familiarize themselves with the manual wire head process. They became more acquainted with the factory's needs. Subsequently, this need was documented and showcased in the virtual exhibition of indigenous localization needs in the system. A call for need was also announced on social networks such as Instagram, WhatsApp, and other platforms where this system is active and where the country's experts are members. After expressing readiness by multiple companies and industrial centers, resumes were evaluated and reviewed. Finally, several options were presented to the technical experts of the requesting factory. After multiple meetings with the presence of these experts and technical factors from the Shamsta system, a suitable option was selected. Following administrative procedures, a contract was signed, and the construction of the automatic wire head machine was carried out.

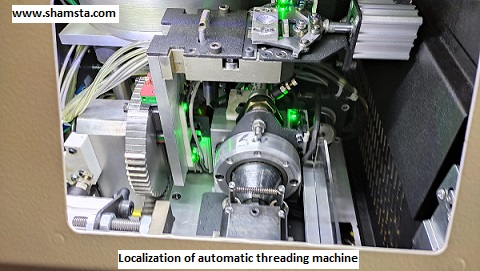

This machine has been built according to the announced requirements and, although there are samples of existing foreign machine videos, it has been developed solely based on the requests of the requesting company and existing work videos, without reverse engineering. This machine, which utilizes cutting-edge technologies, is highly complex, with over 1300 components placed together in small dimensions. It can operate at a speed of 1000 pieces per hour and produce wire heads in four different sizes according to the operator's requirements.

What should be emphasized further is that we can certainly make use of the scientific and executive capabilities of the country's experts and elites, while providing them with opportunities to overcome obstacles, errors, and system issues. Machines that are built for the first time inevitably come with initial shortcomings that need to be identified and addressed during the process, based on the employer's feedback. These issues should not undermine the blossoming potential. We are now delighted that the Shamsta comprehensive industrial system has taken another step towards assisting the country's progress and utilizing the capacities of our experts. With the collaboration and assistance of experts, industrial centers, and relevant organizations, we hope to make further advancements in the localization of our country's industry.